Industry Empowered by Aluminium Extrusion Supplier in Malaysia

ALUMAC, a renowned name in the aluminium extrusion industry, serves a wide range of clientele. As an experienced aluminium extruder and extrusion supplier, we take pride in collaborating with our clients from diverse backgrounds and exceed unique demands from each industry. From anodizing aluminium colors to aluminium thermal break services, our unwavering commitment to excellence ensures that every product meets the highest standards. We supply top-quality aluminium extrusions to a wide range of industries and businesses such as agriculture, industrial sectors and many more.

- Agriculture

- Industrial

- Heating, Ventilation & Air Conditioning (HVAC)

- Cleanroom & Cold Room

- Consumer Durables

Malaysia’s palm oil industry is no doubt the pride of the nation. At the beginning of the all-important refining process is the harvesting, which poses unique challenges due to the height of mature oil palm trees. The harvesting process needs an efficient way of allowing plantation workers to reach the palm oil fruits located several metres above ground.

As an expert in aluminium extrusion, ALUMAC knows that the best, most cost-efficient material to leverage in the harvesting process is aluminium alloy. By employing the correct processes and by controlling the compression throughout the extrusion process, we are able to specially design harvesting poles up to 12m in length that feature high strength and a high degree of ductility. As a result, these flexible, lightweight yet strong telescoping harvesting poles have now become a firm favourite in the field.

ALUMAC also caters to other needs that exist in the agriculture industry. Our expertise is evident in the production of the sturdy, lightweight frames for greenhouses and vertical garden systems that also use aluminium extrusion.

The industrial sector is the powerhouse of a world’s economy. Covering a diverse range of areas, it places an equally diverse set of requirements to suppliers. For example, industrial automation requires highly customized profiles and structures for the rails, tracks and trusses that suit individual automated applications. We specialize in producing tailor-made profile structures, for instance 40x40 profiles, 40x80 profiles and more to get any automated production line up and running reliably.

The growing emphasis on emission reduction has prompted the automotive industry to seek out weight-saving aluminium-based parts and components that deliver both performance and safety. Our technical experience allows us to supply vehicle components and parts such as the chassis, air-conditioner ducts, side steps and more to fulfill the needs of the automotive industry. Besides that, we also supply customized extrusion for manufacturers of high-performance motorcycle rims that require exacting specifications and stringent quality standards.

In the manufacturing of machinery, engineering equipment and machining components, a high degree of precision and accuracy is needed. Our long experience in precision extrusion puts us in the position to propose the best, most cost effective yet robust engineering solutions for the design of machinery, engineering equipment and machining components.

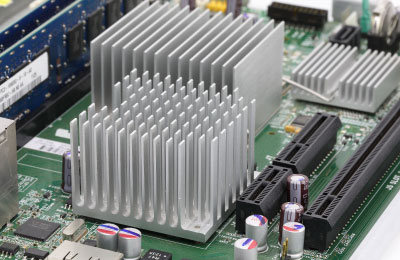

Lastly, ALUMAC’s experience also benefits the electrical and electronics sector which requires components that have excellent conductivity and heat transfer qualities while being lighter and low cost. The big players in the electrical and electronics industry know that ALUMAC is a reliable supplier of aluminium components such as aluminium busbars, heat sinks, equipment enclosures and more. In fact, in recent years we have also become a well-known supplier of extrusions for the manufacturers of LED lighting products.

Offices, laboratories, manufacturing plants, warehouses all depend on efficient, reliable air circulation and ventilation for safety and comfort. This need is taken care of by Air Handling Units (AHU), whose installation requires a lightweight, strong and thermal efficient components to allow them to operate at optimal levels. Additionally, laboratories and R&D centres in the electronic and pharmaceutical industry go one step further in demanding tightly controlled environments that are free from dust and other airborne pollutants that may adversely affect delicate operations. This requirement necessitates ventilation and filtration components that tight fitting to prevent air leaks and contamination.

ALUMAC is adept at both designing and fabricating the vital infrastructure and parts needed to support vital AHU systems. Our aluminium extrusion technology allows the fabrication of strong, custom-made supports, racks and brackets that allow AHU systems to operate at optimal performance in optimal locations. ALUMAC also specializes in designing extrusions that feature a thermal break to achieve required thermal efficiency profiles. To satisfy the additional requirements of laboratories and R&D centres, we are also able to produce the required parts and components with tight tolerances for air filter.

The construction of cleanrooms and cold rooms require high quality structural components that meet high safety standards. As the expert in aluminium extrusions, we easily meet this challenge through our ability to manufacture the full range of custom aluminium frame needed for the ceiling, doors, glass view panels as well as the connection profiles for the accompanying furniture and other accessories. These components can be anodized for durability and produced in compliance with stringent RoHS and REACH requirements for safety and hygiene.

In any industry, consumer durables or user-interfacing items play an important role in improving ergonomics, safety and aesthetics. These items, such as oven & refrigerator handles, , electromagnetic safety lock casings, kitchen cabinet frames as well as sports equipment and more, require the expertise of an aluminium extrusion specialist to produce. Our experience not only allows us to design and manufacture consumer durables but to also add the required surface finishing that further enhances the durability and aesthetics of their design. We offer beautiful yet functional, hard-wearing finishes such as Natural Anodising (NA), Metallic Anodising (METNA) and more to suit your surface finishing requirement for any application.

The manufacturing of sports equipment for example, goalposts and fittings, our aluminium extrusion expertise makes for lightweight, safe and durable products that can be powder coated to perform well during rain or shine. In the manufacturing of bicycle rims, our specialists know how can help create the incredibly strong, lightweight and high corrosion resistance extrusion that’s fit for purpose. It can then be expertly shaped into high performance rim and wheel designs that perform well on the road. As a finishing touch, our anodized process enhances the surface hardness, durability and aesthetics.